DELTARAY – Strategic-Technological Analysis

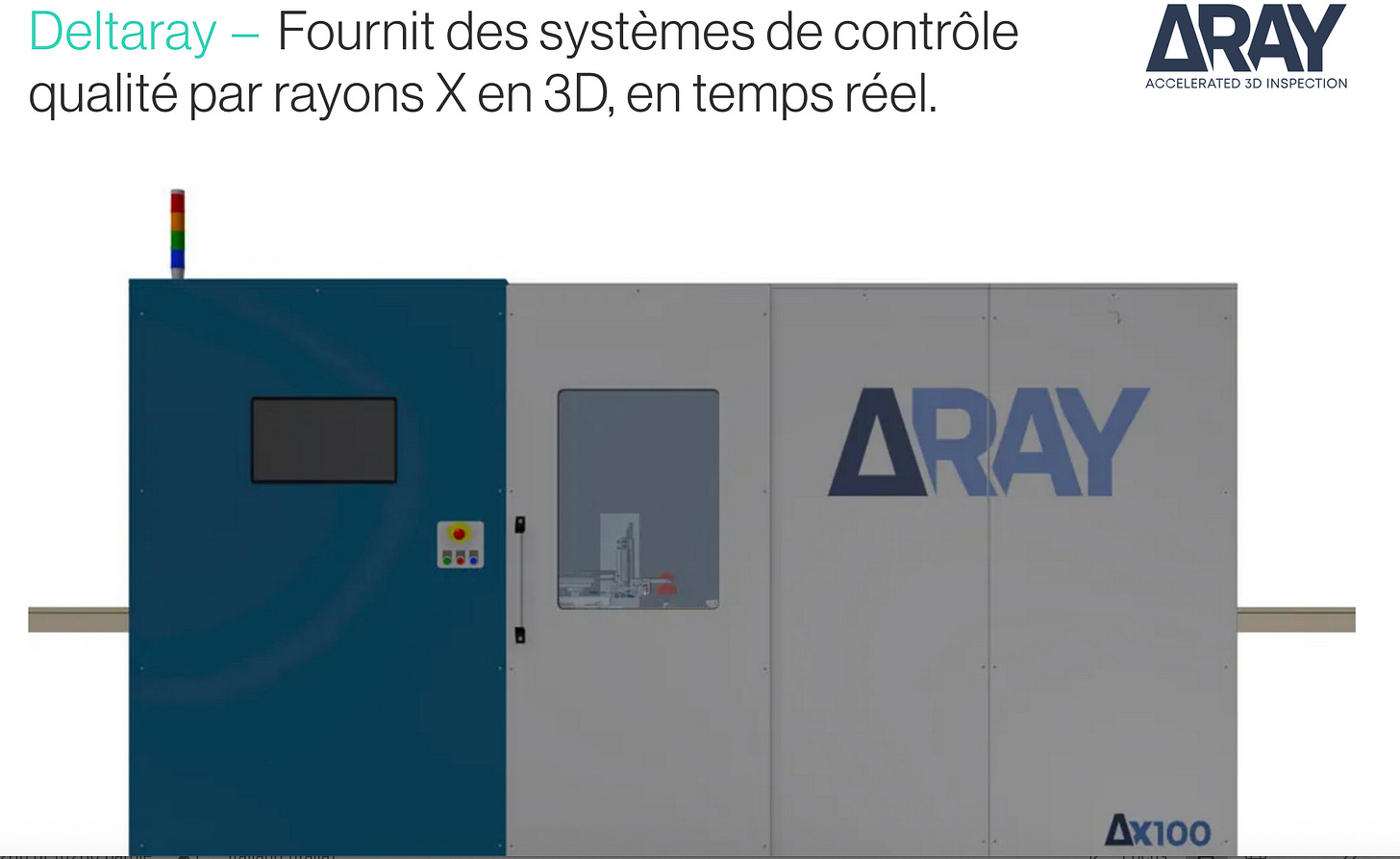

In an era where Europe seeks technological sovereignty and flawless manufacturing standards, Belgium’s Deltaray emerges as a pioneering force in non-destructive inspection. This deep-tech spin-off has developed a breakthrough 3D X-ray scanning system capable of probing the inner secrets of critical components at production-line speeds. Born from over a decade of academic research, Deltaray’s technology marries advanced X-ray imaging with AI-driven analysis to detect microscopic defects that traditional quality checks might miss[1][2]. By enabling “zero defect” manufacturing, the company addresses a crucial link in Europe’s industrial value chain: ensuring that every part used in aerospace, defense, and high-tech sectors meets uncompromising standards without reliance on external suppliers. Deltaray’s story – from its university lab origins to its role in Industry 4.0 – offers a compelling glimpse into how European innovation can bolster strategic autonomy. The following analysis will explore how this young company’s cutting-edge inspection capabilities contribute to Europe’s defense readiness, supply chain resilience, and technological independence, enticing stakeholders to consider the broader implications behind each precisely scanned component.